Description

As explained in the Technical Data Sheet (see the link above), Risol 111/Plus is a innovative and easy-to-use liquid screed reinforcing agent for making low-shrinkage, low-tension screeds. Enhances pumping and workability enormously. Supplied in 20 litre containers.

Key performance advantages:

• CT-C30-F5

• Light foot traffic after 24 hours, light loads after 3 days

• Easy handling to enable correct dosage

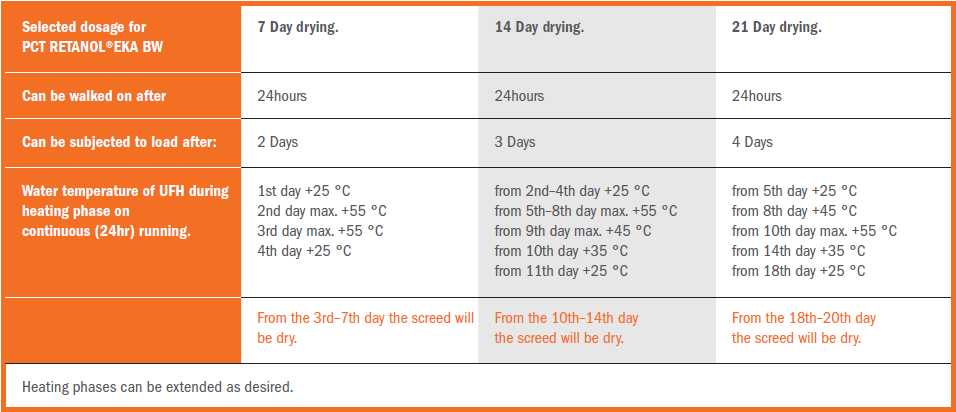

• Screeds can be heated after 5 days. See heating guidelines below

• Excellent application properties, helps to achieve easier and faster levelling with a superior finish insensitive to moisture, therefore suitable for permanently wet areas

• Internal and external use

• UFH pipes require a minimum of 35 mm coverage over the pipe (as per BS 8204)

• Bonded screeds from 25 mm (with ZE Bonding Agent)

• Un-bonded and floating screeds from 35 mm

• PCT Risol Plus is a TUV certified screed product recognised under EU standards as a construction product with no negative impact on human health when added into a floor screed installation

TUV certification

TUV certification involves rigorous testing of the applications for which the product is designed. It includes verification that the product satisfies the strictest European regulations for the industry in which the product was designed for and ensures the product specifications are stated correctly. This is a significant change in the safe use of screed products across the UK construction sector.

The full report is available on request.

Instruction for use

The general guidelines, data sheets and specifications for cement screeds are applicable to the laying and making of PCT Risol Plus screeds.

Application temperature: +5 °C to max. +28 °C (ambient and substrate temperature).

Apply PCT Risol Plus within 90 minutes after mixing. Higher temperatures will reduce and lower temperatures increase the working life of the screed mix.

MIXING INSTRUCTIONS

Min 50 kg cement per 250 litres standard screed pump vessel – please refer to the PCT Cement Approval list for suitable types of cement.

Dosage: in standard screed pump mixing vessels with 250 litres gross capacity

(5 pump fillings are assumed at 200 litres each, amounting to 1 m³)

Dosage: 0.2 % of cement weight.

100 mls with 50 kg of cement will produce minimum screed strength CT-C25-F4

150 mls with 62.5 kg of cement will produce minimum screed strength CT-30-F5

Reduce the water accordingly as less will be required.

Fill the screed pump to about one-half with sand and the entire amount of cement (50 kg) as usual. Add PCT Risol Plus followed by the first mixing water (usually 5–10 litres) and then fill the pump completely. Gradually add the required amount of residual water until a pliable consistency is obtained.

A simple test for on site moisture checking is the “damp earth test”. By squeezing a handful of mortar tightly with a gloved hand, when released, the sample should retain its shape and leave the gloved hand slightly moist without running water.

Note: A mixing time of 2 minutes ensures proper blending of the products.

PCT Risol Plus must never be mixed with other screed or mortar additives.

It is important to prepare the screed mixture correctly by ensuring you select the approved cement type, cement quantity and aggregates in accordance with DIN 1045-2, grading curve A/B, 0–8 mm, for making floor screed. 0–4 mm aggregates may affect drying time and strength.

GENERAL POINTS

Never reactivate screed mortar which is already setting by adding additional water. This also applies to mechanical and manual finishing. Do not apply additional PCT Risol Plus to a screed that is already setting. Protect the screed from draught, direct sunlight and excessive heat during the entire application. It may be necessary to darken large window fronts and floor-level glass facade areas to prevent over drying. Moisture testing can only be determined using a CM (carbide method) measuring device. Electronic moisture measuring devices may not be used on Retanol screeds.

WINTER RULES

The application of cement screeds in winter at too low temperatures always presents a risk. Not without reason does the cement industry specify a minimum temperature of ≥+5 °C for the application of cement. Below this limit, cement reacts very slowly or not at all. The desired strengths and other screed properties might not be obtained.

For PCT Risol Plus we have summarized the following “12 Golden PCT Winter Rules” for you:

1. Too cold: refuse the application.

Always follow the BS8204 along with all other relevant guidelines including this Technical Data Sheet.

2. Heat the mixing location and building to at least +5 °C.

Heat the mixing location and building so the cement, aggregates and applied screed do not freeze, and the temperature does not fall below +5° C.

3. Do not use heating lances.

The use of heating lances for heating the screed sand has negative effects on both the sand itself as well as the screed mortar.

4. Room climate: max. +15 °C temperature & min. 45% air humidity.

The temperature difference between the outside and inside of the building must not vary by more than +15 °C. Furthermore a minimum of 45% rH is recommended inside the building. This prevents thermal shock effects, rapid surface drying and excessive deformation.

5. Do not use floor heating during application.

Use other heating methods for “frost protection”. It is not recommended to use floor heating – even at low temperatures. Large deformations frequently occur at joints and edges when using floor heating during application.

6. Avoid warm airflows on and near the screed.

Caution regarding heating systems! “Forced heating” in the building may result in too rapid drying. High temperatures and strong blowers cause detrimental air movement.

7. Heat the building beforehand.

Start heating the building at least 5-6 days before screed application. This time is necessary for obtaining the required temperature in cold buildings.

8. Do not use kiln-dried sand.

9. Do not use antifreeze agents.

10. Warm water is no help.

Example: If the base materials i.e. sand and cement are at a temperature of 0 °C, the addition of +30 °C warm water will only increase the temperature of the screed mixture by +1.6 °C. At this temperature neither the cement nor the additives react. Warm water is however suitable for cleaning conveyors and tools.

11. Never leave additives and cement outdoors in vehicles overnight.

Additives and cement must never be stored outdoors in vehicles overnight in the winter season.

12. Warm up.

In warm water, at temperatures of about 15 to 20°C, PCT RETANOL® achieves an ideal viscosity and is fully effective.

PCT Risol Plus is suitable for almost all conditions on the construction site. At low or extremely high ambient and substrate temperatures and high relative air humidity (> 70 %) the curing and drying times may be slightly longer. This data refers to the comparison with ambient conditions at +20 °C and a relative air humidity of 60 %. Air exchange is however obligatory. Please refer to PCT guidance on the regular ventilation of rooms. Screed surfaces must be neither partly nor fully covered during the drying process. This must be observed by the client.

WHEN CAN SCREEDS BE WALKED ON AND SUBJECTED TO LOAD?

PCT Risol Plus screeds can be walked on 24 hours after application. They can be subjected to load if exposed to standard site traffic after 3 days. This means that rolling loads such as wheelbarrows can be used with a maximum load of 100 kg.

Note: PCT Risol Plus screeds are floor levelling screeds. Observe British Standards when point-loading.

Subjecting the floor to loads too early may result in damage to the screed surface and/or the screed structure and/or promote crack formation.

Screed vibrations must be permanently avoided.

The expansion foam strips must not be cut off before the laying of floor coverings or the grouting process for laying tiles has been completed, and this must be done by the floor installer.

DRYING AND VENTILATION OF ROOMS WITH HEATED AND UNHEATED PCT RISOL PLUS SCREEDS

Danger: premature drying and air circulation can cause additional deformation in the screed, especially in the areas around joints this often results in concave curling or lipping which cannot be rectified, along with a possible height offset between the screed sections. This also increases the risk of crack formation.

Avoid all draughts! This applies to all types of screed.

The heating engineer must prepare a record on the initial heating and the subsequent commissioning. The signed record must be handed over to all relevant parties and contain the following information: All heating data with respective flow temperatures and maximum flow temperature attained, operating conditions and outdoor temperature upon handover and date of commissioning.

UFH SYSTEMS – HEATING AND COMMISSIONING

The data in the PCT Risol Plus heating records must be complied with during the continuous heating phases. The entire heating phase described below must take place over 24 hours for each temperature step with the heating control on constant. The individual flow temperatures (water, not room temperature) must be set manually. System-controlled, automatic heating programmes must not be used.

On the 28th day after completion of the screed application and after completion of the heating phases, the CM measurement can be executed. The heating process can be repeated if necessary. If a maximum flow temperature of +55 °C cannot be obtained, the maximum flow temperature obtainable by the heating system must be set from the 18th day and maintained up to the 24th day.

The floor temperature must be adjusted to the floor finishing manufacturer’s requirement.

This heating information is only valid when used with this technical data sheet.

A CM moisture test must be performed before installing the final floor covering.

Shelf life of 9 months stored in ideal conditions.

All the information on this product given above is based on extensive practical experience and tests undertaken by PCT Performance Chemicals GmbH. However, it is not possible to take all construction site conditions into account and to give suitable instructions for use in each case. It is therefore recommended to verify the applicability, appropriateness and practicability of this information and the intended measures by means of individual tests. PCT assumes responsibility for the accuracy of this product information and the described properties as well as for the effect of the product. PCT reserves the right to change the product specifications. If the site is or has been supervised by PCT the user is under no obligation to check applicability and appropriateness.